2020 Mercedes-Benz EQC Electric SUV

Mercedes-Benz is flipping the switch. The new EQC is …

… The first Mercedes-Benz under the product and technology brand EQ

- EQ stands for "Electric Intelligence"

- It is derived from the Mercedes-Benz brand values of "Emotion" and "Intelligence"

- The EQC is part of a growing family of all-electric vehicles from Mercedes-Benz

- Conceived to meet all the requirements for a battery-electric drive system

- Convincing in the sum of its attributes with respect to Mercedes-Benz comfort, quality and operating range

- An estimated electric range of around 200 miles

… Progressive in design

- Pioneer of an avant-garde electric look

- Progressive luxury design points the way to the future

- Large black-panel surface as a striking front feature

- Optical fibers as a visual link to the torch-like daytime running lamps

- Sporty, stretched silhouette

- Innovative interior design inspired by the world of consumer electronics

… Excitingly dynamic

- A dual motor electric drivetrain at each axle, with a combined output of 402 horsepower

- Superior and confident driving characteristics of an all-wheel drive vehicle

- Various driving modes with different characteristics

- Battery recuperation can be adjusted as the customer requires, using gearshift paddles behind the steering wheel. In "D Auto" mode, the EQC can adapt recuperation according to the traffic ahead with the aid of ECO Assist

… The Mercedes-Benz among electric vehicles

2020 Mercedes-Benz EQC

2020 Mercedes-Benz EQC

- Latest-generation driving assistance systems including Active Distance Assist DISTRONIC and Active Steering Assist

- Extensive crash test programs, meeting strict Mercedes-Benz requirements

- Stringent additional tests completed for the battery and all components carrying electrical current

- Pre-climatization for a comfortable cabin upon arrival in all temperatures

- Extremely quiet interior

- Trailblazing MBUX multimedia system - Mercedes-Benz User Experience with numerous EQ-specific functions

- Integration into ongoing series production at the Mercedes-Benz plant in Bremen

- Battery produced by the Daimler subsidiary Deutsche ACCUMOTIVE

… More than just a car, and a symbol of a new era of mobility

- Comprehensive services for electric mobility for today and tomorrow

- Relaxed, uncomplicated travel with transparency and planning certainty

- Dialogue with visionaries, business people and opinion leaders in the "EQ Community"

- New event formats "EQ Dinner" and "EQ Nights"

- Entry into Formula E for the 2019/2020 season

The new Mercedes-Benz EQC

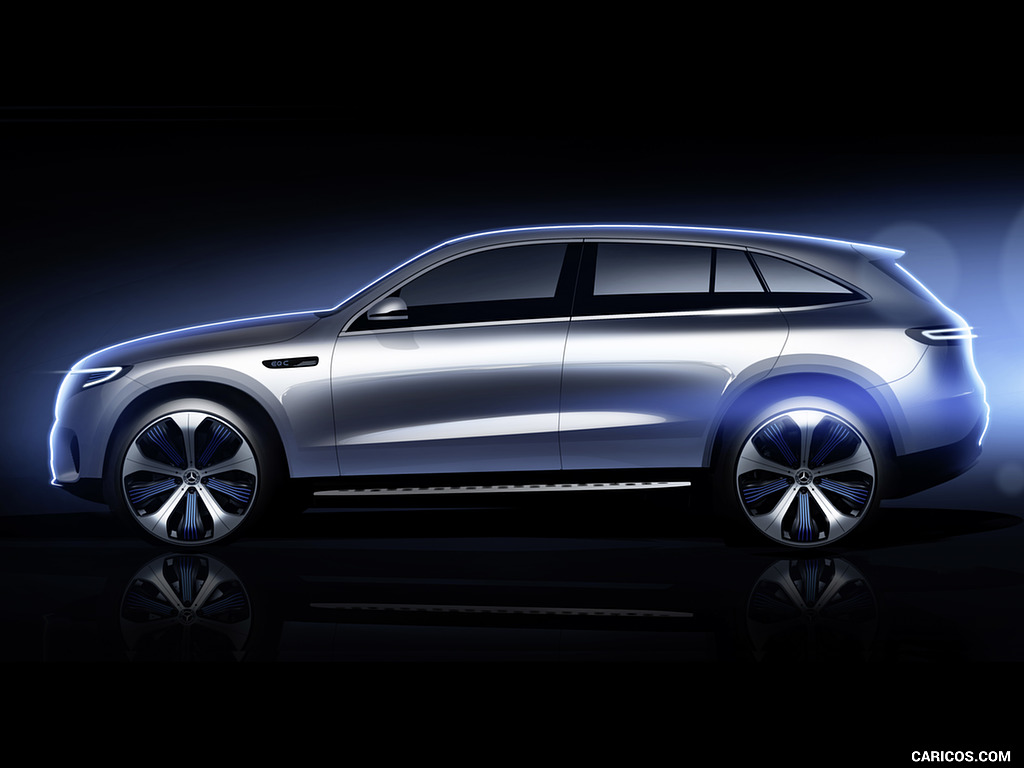

It was at the 2016 Paris Motor Show that Mercedes- Benz first presented its new product and technology brand for electric mobility. In mid-2019, the EQC will be the first Mercedes-Benz vehicle to be launched globally under the EQ brand. With its seamless, clear design, it is a pioneer for an avant-garde electric look while representing the design idiom of Progressive Luxury. With respect to quality, safety and comfort the EQC is the Mercedes-Benz among electric vehicles, and highly convincing in the sum of its attributes. These are accompanied by dynamic performance, thanks to two electric motors at the front and rear axles with a combined output of 402 horsepower. A sophisticated operating strategy enables an estimated electric range of around 200 miles (preliminary estimate). EQ also offers comprehensive services with Mercedes me connect, which makes electric mobility convenient and suitable for everyday driving. The EQC also symbolizes the start of a new mobility era at Daimler. The EQC will celebrate its World Premiere in Stockholm on September 4, 2018 and will go on sale in the U.S. in 2020.

As the first Mercedes-Benz model under the new product and technology brand EQ, the Mercedes-Benz EQC has many trailblazing design details and color highlights typical of the brand. Both inside and out, the EQC embodies the design idiom of Progressive Luxury. This arises from the combination of digital and analogue elements as well as the seamless merging of intuitive and physical design.

By virtue of its muscular proportions, the EQC is classed as a crossover SUV. The extended roofline and window layout with a low shoulderline and the coupe-like roof visually position it between an SUV and an SUV coupe.

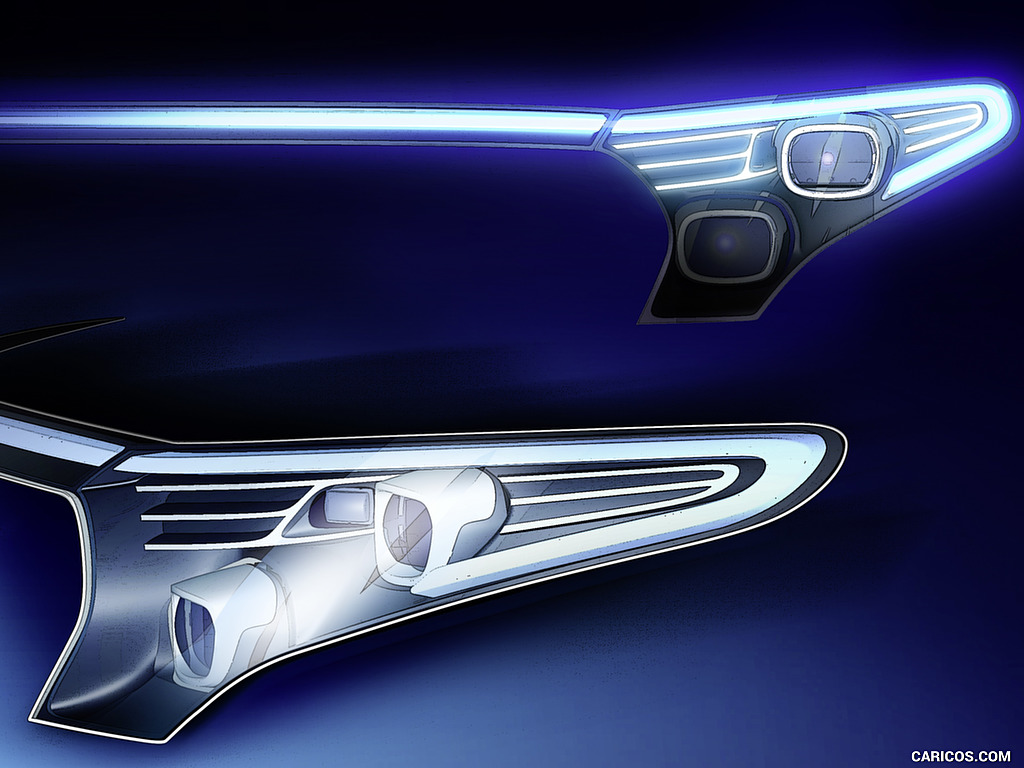

A striking feature at the front is the large black-panel surface combining the headlamps and grille. For the first time, the black panel is bordered at the top by an LED Light Band as a visual link between the torch-like daytime running lamps. At night, this creates an almost uninterrupted, horizontal light band.

The high-quality interior of the EQC also pioneers an avant-garde electro-look. One example is the louvered edges of the upper dashboard and door trim which resembles the cooling fins of a hi-fi amplifier. The instrument panel is designed as a driver-oriented cockpit. The unmistakable Mercedes-Benz wing profile is asymmetrical, with a "cut-out" in the driver area. This is where one of the visual highlights of the cockpit is located - a high-tech, high gloss housing with rectangular air vents with key-shaped, rose-gold colored louvres.

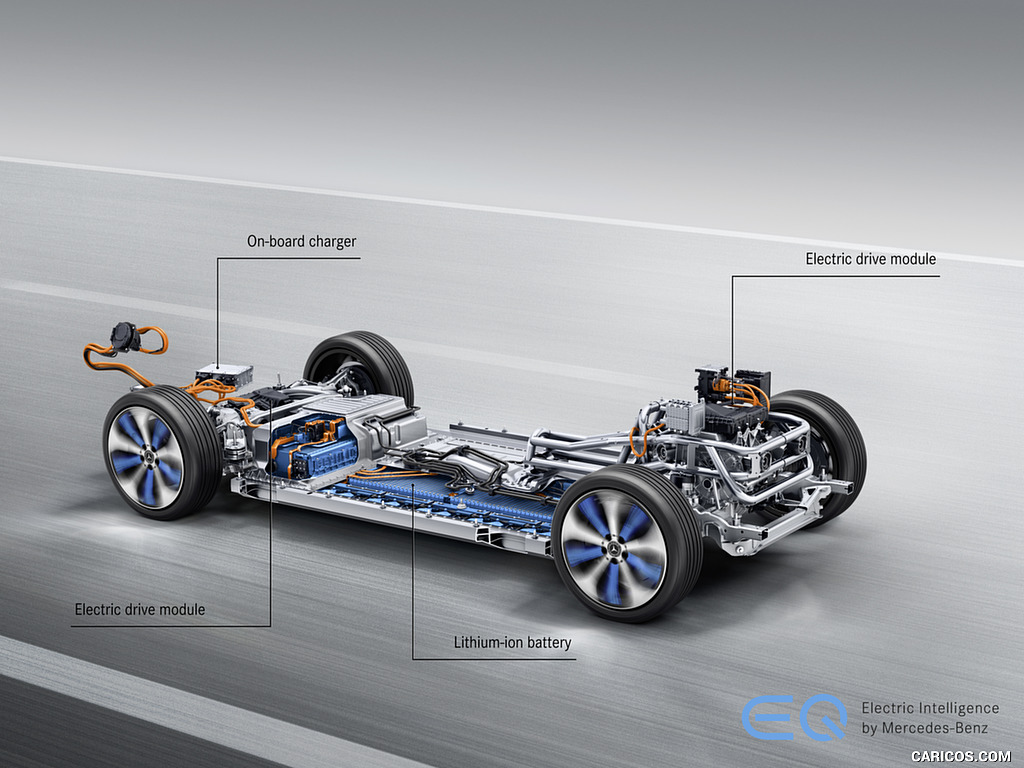

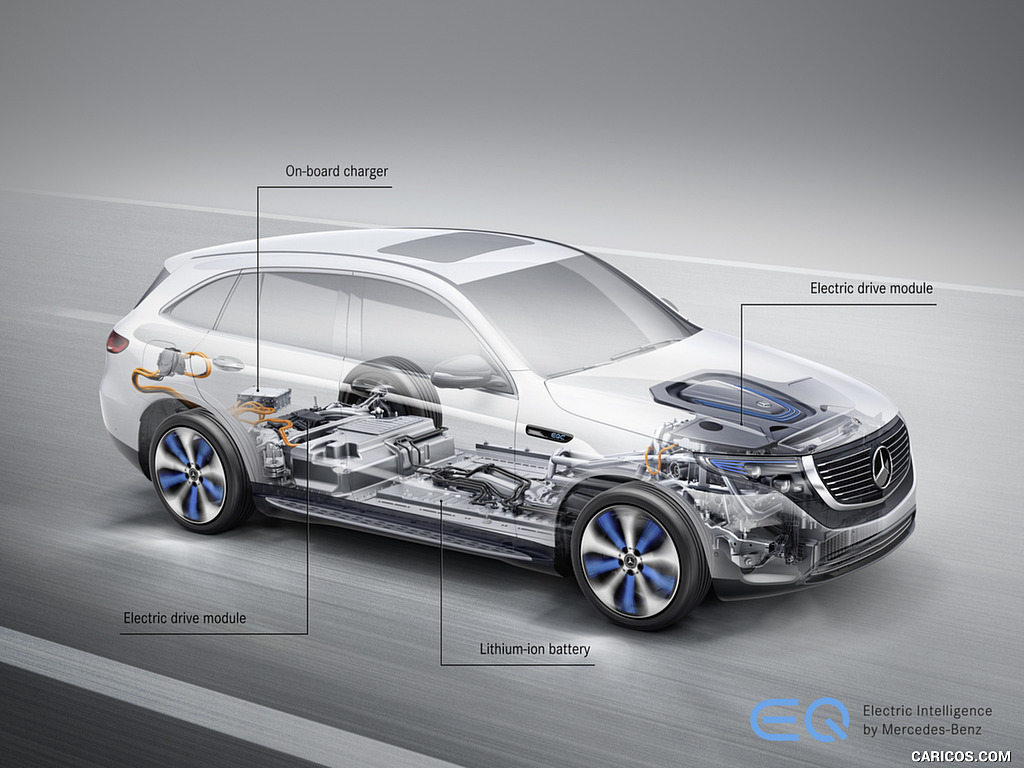

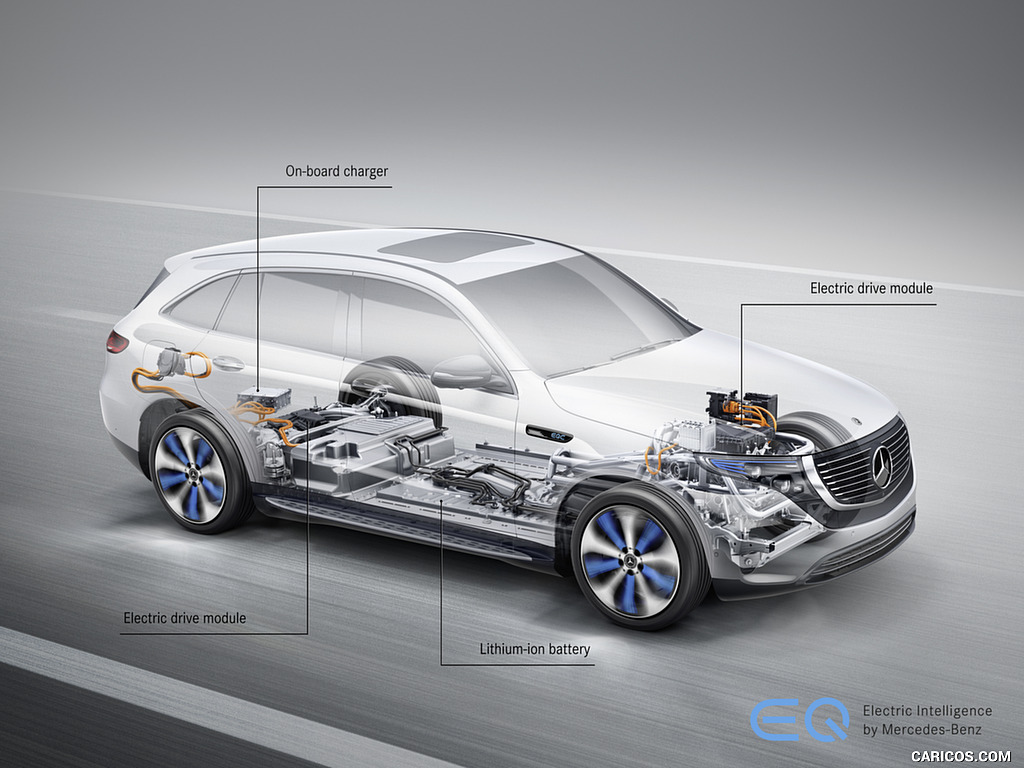

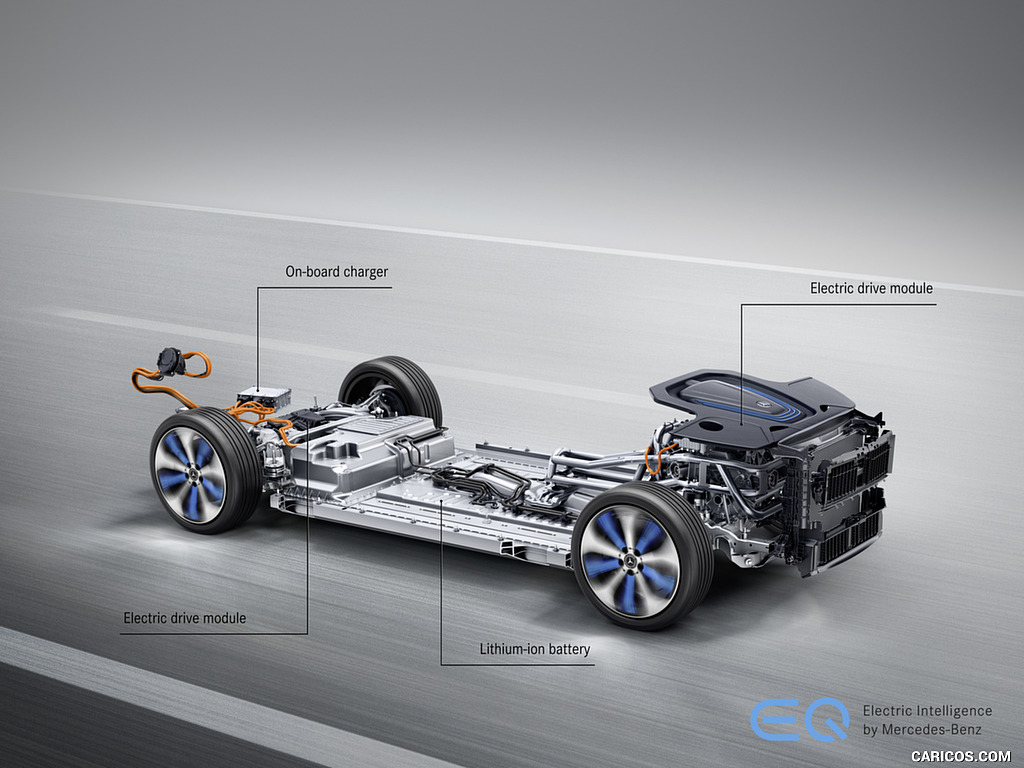

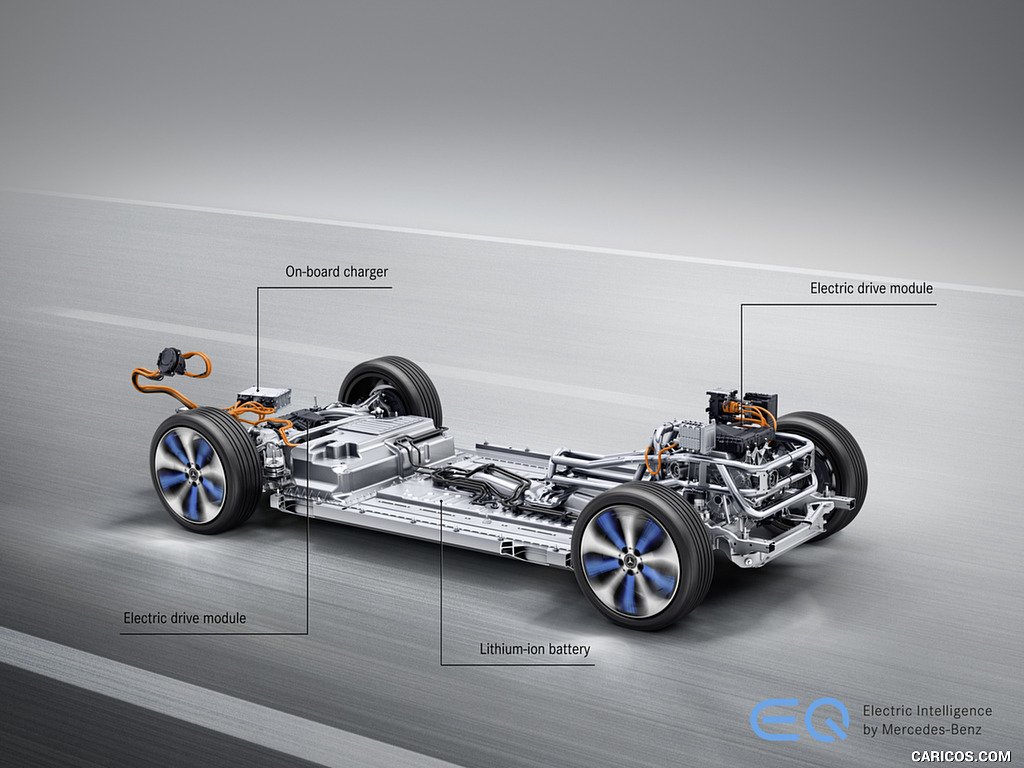

Powertrain: Dynamic performance meets efficiency

As the first Mercedes-Benz model to be launched under the new product and technology brand EQ, the EQC features an all-new drive system development with compact electric drivetrains at each axle. These give the EQC the confident and dynamic driving characteristics of an all-wheel drive vehicle.

To reduce power consumption, the electric drivetrains are configured differently: the front electric motor is optimized for best possible efficiency in the low to medium load range, while the rear motor adds sportiness. Together, they generate an output of 402 hp and a maximum torque of 564 lb-ft.

Mercedes-Benz engineers have enhanced noise comfort with a number of measures. In the EQC the powerpacks are isolated by rubber mounts at two points: where the powerpack connects to its subframe and where the subframe connects to the body. This effective isolation is supplemented with insulation measures. As a result, the interior of the EQC is extremely quiet.

The lithium-ion battery, which has a usable energy content of 80 kWh supplies the vehicle with power. The power consumption and range of electric vehicles depends very much on the driving style. The EQC supports its driver with five driving programs through DYNAMIC SELECT, each with different characteristics: COMFORT, ECO, MAX RANGE, SPORT and INDIVIDUAL for an individually customizable program. In the more economical driving modes, the haptic accelerator pedal that prompts the driver to conserve power plays an important role. The driver is also able to influence the recuperation level using paddles behind the steering wheel.

The ECO Assist system gives the driver comprehensive support by prompting the driver when it is appropriate to lift off the accelerator, for example when the vehicle is approaching a change in speed limit, and by functions such as coasting and specific control of recuperation. For this purpose, navigation data, traffic sign recognition and information from the intelligent safety assistants (radar and stereo camera) are linked and processed.

Technical data*

| Estimated Range | Up to 200 miles |

| Drive system | 2 asynchronous motors, all- wheel drive |

| Rated output | 402 hp |

| Peak torque | 564 lb-ft |

| Top speed (mph) | 112 mph (electronically limited) |

| Acceleration 0-60 mph | 4.9 s (est.) |

| Battery | Lithium-ion |

| Battery capacity | 80 kWh |

| Length / width (width with mirrors) / height | 187.4 / 74.2 (82.5) / 63.9 in |

| Track width (F/R) | 64.0/63.6 in |

| Wheelbase | 113.1 in |

*provisional data

Charging: Flexible and fast

As standard, the EQC is equipped with a water-cooled onboard charger (OBC) with a capacity of 7.4 kW, making it suitable for fast AC charging at home or at public charging stations.

Charging at a home wallbox is up to three times faster than at a domestic power socket. It is faster still with DC charging – which is standard for the EQC – for example via CCS (Combined Charging Systems) in Europe and the USA. Depending on the SoC (status of charge), the EQC can be charged with a maximum output of up to 110 kW at an appropriate charging station. In around 40 minutes, the battery can be charged from 10 - 80 percent SoC (provisional data).

The multimedia system MBUX: with EQC-specific functions

The EQC features the innovative multimedia system MBUX - Mercedes-Benz User Experience - which has numerous EQ-specific functions such as the display of range, charge status and energy flow. EQ-optimized navigation, driving modes, charging current and departure time can also be controlled and set via MBUX.

The MBUX touchscreen display has a special EQ menu where numerous EQ features are grouped. Alternatively the user can access the EQ menu of the MBUX system directly using a hard key in the lower left control panel. Thanks to natural language recognition, the EQ-specific voice control helps the driver to operate the EQC.

Intelligent services: Relaxed travel from start to finish

EQ with Mercedes me connect provides comprehensive services for the electric mobility of today and tomorrow. The most important new services and functions of the EQC planned for market launch include:

Pre-entry climate control: This ensures that the vehicle interior is at the desired temperature on departure. It can be programmed directly via MBUX or via the Mercedes me connect App. A sophisticated system with a heat pump and electric heater boosters pre-climatizes the interior for optimal comfort in the cold winter or hot summer days.

The EQ-optimized navigation bases its calculation on the fastest route, taking into account the shortest charging time. The route planning also responds dynamically to changes, and can take place both offboard and onboard, externally (via the Mercedes me connect App) and within the vehicle. Thanks to EQ-optimized navigation, Mercedes-Benz customers can easily find charging stations, and Mercedes me Charge gives them convenient access to the charging stations of numerous providers.

Active and passive safety: EQC-specific safety concept

The EQC is equipped with the latest generation of Mercedes-Benz driver assistance systems. In the Driver Assistance Package, these include new functions such as predictive speed adjustment when approaching traffic: when traffic is detected, Active Distance Assist DISTRONIC® reduces the speed as a precaution.

The EQC also meets the highest requirements with respect to passive safety: in addition to the usual, extensive program of crash tests, Mercedes-Benz applies further, particularly stringent safety standards to the battery and all component parts carrying electrical current. These standards exceed legal requirements. The vehicle structure of the EQC has been adapted to suit the special requirements of the electrical components and battery, and is configured to achieve the usual high safety level. For example, a new subframe surrounds the drive components located in the front section, and this unit is supported by the usual mounting points.

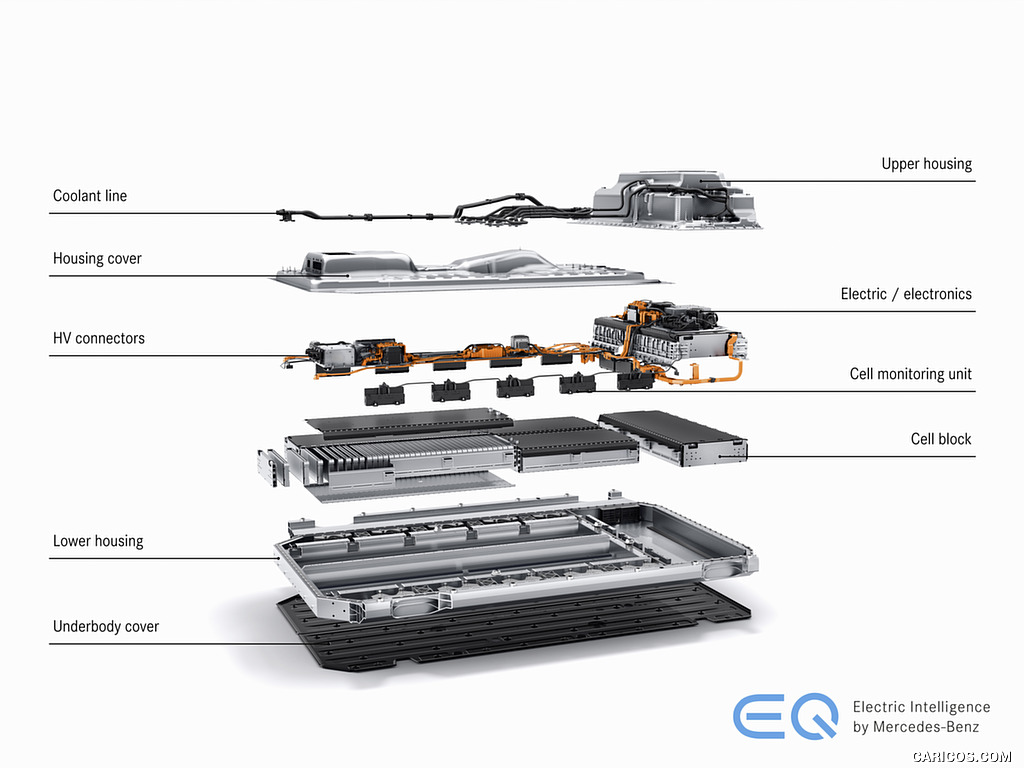

Mechanical protection of the battery: the high-safety design begins with the installation position of the high-voltage battery beneath the vehicle floor. The energy storage unit is surrounded by a stable frame that can absorb energy. Deformation elements are installed between the frame and the battery, and these are able to absorb additional forces in the event of a severe side impact. A battery guard in the front area of the battery is able to prevent the battery from being pierced by road debris.

Electrical protection of the high-voltage system: the extensive experience of Mercedes-Benz with high-voltage drive systems has led to a multi-stage safety concept that deploys in the event of an accident. The high-voltage system automatically shuts down, according to the severity of the accident. There are also shutdown points where emergency teams can deactivate the high-voltage system manually.

Testing: Endurance tests around the world

By market launch, 200 prototypes and pre-production vehicles of the EQC will have covered several million miles across four continents (Europe, North America, Asia and Africa). The test program comprises more than 500 individual tests. Like all Mercedes-Benz vehicles, the EQC must pass all of the demanding test programs. There are also special tests for the electric powertrain, the battery, and the interplay of all powertrain components.

In the process the test experts are able to build upon the extensive findings from their digital testing work, used to ensure both the buildability of the vehicle and for the simulation of crash behavior, aerodynamics and NVH (noise, vibration, harshness). In addition there are intensive tests on numerous test rigs at the Mercedes-Benz Technology Center in Sindelfingen. The ratio between digital and real testing is roughly 35 to 65 percent.

Production: Preparations in full swing in the Bremen plant

Production of the EQC will start in 2019 at the Mercedes-Benz plant in Bremen. The new EQC will be integrated into ongoing series production as a fully electric vehicle, and the very latest production technologies will be employed.

In typical series production, the joining of the powertrain to the body is called the "marriage." One decisive innovation is the battery-joining center where the EQC undergoes a second "marriage" following installation of the two electric motors in the bodyshell. This is where the EQCs are equipped with a battery for the first time. The body is suspended from a C-carrier and deposited on a frame. Support arms raise the battery to the vehicle's floor from below, and an employee monitors the automatic bolting in place.

In parallel with this, production of our own batteries for the EQC is coming on stream at the expanded battery plant in Kamenz (near Dresden) Germany.

End-to-end mobility from the inventor of the automobile

It was at the 2016 Paris Motor Show that Mercedes-Benz first presented its new product and technology brand for electric mobility: EQ. The name stands for "Electric Intelligence" and is derived from the brand values of "Emotion and Intelligence." The goal has been clearly defined: within a very short time, EQ is to become one of the most desirable electric-technology brands in the automobile sector. Excitement and fascination are just as important as the message about holistic solutions that provide maximum customer benefit with state-of-the-art technologies. At the same time, EQ uses electrification to create added value that cannot be achieved with conventionally powered vehicles.

The brand includes major aspects that make entry into the world of electric mobility as easy as possible for customers. Accordingly, EQ is a comprehensively positioned brand that goes well beyond the vehicle itself. EQ offers a comprehensive ecosystem of products, services, technologies, innovations and inspirations. Alongside the vehicle family via Mercedes me connect the brand provides comprehensive services that make electric mobility more convenient and accessible. The intelligent services and functions available for the EQC extend from route planning and remote pre-climate control to new assistance functions and convenient charging.

In the increasing broad portfolio of Mercedes-Benz, the EQ brand provides easy and transparent guidance for customers interested in electric drive. For the brand as a whole, EQ is a further, logical step within the Mercedes-Benz strategy of "Best Customer Experience." All in all, more than ten billion euros will be invested in expansion of the electric fleet in the next few years, and an additional billion in battery production. At the same time we are also investing in the systematic expansion of the charging infrastructure.

On the road to locally emission-free driving, the company is following a three- track drive strategy with electric vehicles (EQ), plug-in hybrid models (EQ Power) and 48-Volt mild hybrid combustion engines (EQ Boost).

Brand philosophy and brand experience for the mobility of the future

With EQ, Mercedes-Benz has set the scene for the future. The entire know-how of Mercedes-Benz Cars relating to intelligent electric mobility is consolidated into this brand. At the same time EQ is creating a new and unmistakable brand look. Just as Mercedes-Benz stands for Modern Luxury, Mercedes-Maybach for Ultimate Luxury and Mercedes-AMG for Performance Luxury, EQ is pointing the way to the future with Progressive Luxury.

Featuring a completely new design, the battery-electric models will have their own distinctive "electro-look" styling (see Design section).

Communication with a mission: "Educate, Entertain, Inform"

Four topic areas will fundamentally transform the mobility of the future: the increasing connectivity of vehicles, autonomous driving, the development of digital mobility and transport services and electric mobility. With EQ, the company already offers a comprehensive range of services for electric mobility.

In its communication, the motto of EQ is "Educate, Entertain, Inform." This means that factual information is coupled with a surprising, at times humorous presentation heavily characterized by visual content. In this way complex inter-relationships such as technical features relating to electric mobility are tangibly and simply explained. The aim is not only to increase awareness of the EQ brand, but also to promote general acceptance of electric mobility amongst customers, potential customers and society in general. In the second phase, which is now beginning with the world premiere of the brand's first Mercedes-Benz vehicle, the focus is on hallmark Mercedes-Benz attributes, including quality, safety, comfort and design, which influence the individual's decision to buy. In this way customers are being prepared for the market launch of the EQC.

Experiencing Electric Mobility

When the sixth season of the ABB FIA Formula E Championship commences, Mercedes-Benz will open a new chapter in its long and successful motorsport history. At the start of the 2019/20 season, two fully electric racing cars will be fielded by the new Mercedes EQ Formula E team for the first time. In 2018 Mercedes-Benz with its EQ brand has already been involved as a partner in the European Formula E races in Rome, Paris, Berlin and Zurich. For EQ, Formula E is far more than a motorsport championship, but instead an exciting festival that attracts progressive people with urban lifestyles and new target groups. Visitors to Formula E are interested in mobility, cars and alternative drive systems.

EQ Community – shaping the future of mobility

A further initiative that exposes EQ to new target groups is the "EQ Community." This is based on the conviction that EQ is best able to meet the challenges of the mobility of tomorrow by entering into a dialogue with visionaries, businesspeople and opinion leaders. Accordingly EQ has a specific presence in the environment of these target groups at international, innovation-oriented and trendsetting conferences such as the Tech Open Air (TOA, the leading European interdisciplinary technology festival in Berlin), the Collision (Jazz) Festival in New Orleans, and the Web Summit in Lisbon or the RISE (Tech Conference) in Hong Kong.

With "EQ Dinner" and "EQ Night," Mercedes-Benz has created two solid event formats in which inspiring personalities come into contact with the brand and engage in an exchange about the mobility of tomorrow with like-minded individuals. EQ seeks to inspire, and also looks for inspiration from the members of the Community.

The exclusive EQ Dinners are small-scale events under the motto "share the table – and shape the future." This is where future experts from Daimler come together with invited visionaries to discuss approaches for shaping the future of mobility. A wider public takes part in the EQ Nights. Their purpose is both to familiarize interesting and inspiring personalities with the EQ brand and to discuss the mobility needs of today and tomorrow with the guests. The objective is to better understand and cater for mobility needs. After the events, dialogue within the EQ community continues on digital channels such as the Mercedes Brand Hub, Mercedes-Benz social media channels and the EQ LinkedIn presence. In this way EQ provides many ways in which its community and the visionaries can exchange views with the brand and between themselves.

Design

Progressive Luxury: Pioneer of a new electro-look

As the first Mercedes-Benz model launched under the new product and technology brand EQ, the EQC features pioneering design details and hallmark color accents. As a particularly striking feature, the headlamps and grille blend into a black-panel surface. The high-quality interior of the EQC also pioneers an avant-garde electro-look. The innovative interior design is inspired by the world of consumer electronics. One example is the louvered trim in the upper dashboard and door panels, which resembles the cooling fins of a hi-fi amplifier. Both inside and out, the EQC embodies the design idiom of Progressive Luxury.

The EQ brand gives an insight into the future, and is shaped by an avant-garde, distinct look – Progressive Luxury. This arises from the combination of a previously unknown beauty, the conscious clash of digital and analogue elements as well as the seamless merging of intuitive and physical design.

By virtue of its muscular proportions, the EQC is classed as a crossover SUV. The extended roofline and window layout with a low shoulderline and the coupe-like roof visually position it between an SUV and an SUV coupe.

For the first time, the black panel is bordered at the top by an LED Light Band as a visual link between the torch-like daytime running lamps. At night this creates an almost uninterrupted, horizontal light band. In certain markets this unmistakable night design is supplemented with an illuminated central Mercedes-Benz star. This standard feature has been combined with the radar sensor of Active Distance Assist DISTRONIC for the first time, and acts as an additional position lamp for the vehicle.

Other design features at the front include the air inlet with two chrome louvres in the lower area of the front apron and the simulated side air inlets in high- gloss black.

The lower section of the bumper is in black. Together with the black side trim and the lower section of the rear bumper, this produces a well-balanced overall effect. Moreover, this color concept together with the low shoulderline visually lowers the vehicle height and ensures an off-road- look.

At the rear the sporty, stretched silhouette is finished off by a low roof spoiler. The roof contour and side window layout visually confirm that the EQC is conceived as a crossover SUV. The side windows are framed by high-gloss aluminum trim strips. The charging flap is integrated flush with the rear right side wall.

Roof rails have deliberately been omitted, preserving the clear, monolithic form and further enhancing aerodynamics. As with other Mercedes-Benz car models, robust attachment points integrated into the roof structure allow carrier systems to be mounted.

The EQC is fitted with 19 to 21-inch, aerodynamically enhanced, bicolor light- alloy wheels, which are flush with the wheel arches. Two wheel variants have blue touches on the rim flange or spokes.

The deep roof spoiler adds to the excellent aerodynamics and emphasizes the width of the rear window. The transition between the bumper and tailgate is practically seamless. The multi-section rear lights with tail lights in edge-light technology echo the light band at the front. The reflectors are positioned separately in the bumper. This allows a flatter, sporty layout for the rear lights. The multi-section chrome strip in the lower area of the bumper emphasizes the visual breadth of the rear end.

As in Mercedes-Benz coupes, the license plate is located in the bumper. This makes the Mercedes star in the tailgate particularly prominent. This is also used to open the tailgate, and accommodates the standard rearview camera.

The model lettering EQC is located on the left of the tailgate, and has a new, EQ-specific typography in chrome.

Interior design: Progressive design idiom, modern materials

The high-quality interior of the EQC also pioneers an avant-garde electro-look. This applies to the form, material mix and user experience. There is a unique contrast between sensuous, soft surfaces, precise edges and geometrical shapes.

The instrument panel is designed as a driver-oriented cockpit. Both in volume and complexity, its upper section is reduced to what is essential. The signature Mercedes-Benz wing profile is asymmetrical, with a "cut-out" in the driver area. This is where one of the visual highlights of the cockpit is located - a high-tech, high gloss housing with rectangular air vents with key-shaped, rose- gold colored louvres. These are a feature of the new EQ design idiom, and are exclusive to this new model.

The instrument panel has a louvered metal surround reminiscent of the cooling fins found on high-quality music amplifiers. This design feature is a wrap- around extending into the doors. The simulated, metallic-look louvered rim continues into the door panels as a design highlight, and has integral mid- range speakers. This creates a harmonious contrast between high-tech aesthetics and classic door trim. The perforated plate feature is another repeated design motif. It is found at the top of the instrument panel support and in the mirror triangles. Round depressions of different diameters create a dramatic three-dimensional pattern. With the Burmester® Sound System, the mirror triangle accommodates the tweeter and has the familiar metallic look with a pattern of perforations and a key signature.

The instrument cluster and media display (two 10.25-inch displays standard) are housed behind a shared, continuous glass surface to form a large, free- standing screen. There is a touchpad in the center console as a further means of controlling many vehicle functions. The optional 64-color ambient lighting impressively illuminates the instrument panel, with LED lights coursing through the entire cockpit and across the deck with the air vents.

The EQ character of the interior is accentuated by a brand-specific color scheme that is unique in the Mercedes-Benz portfolio. High-grade materials such as leather, plus modern trim elements in an aluminum look or with natural grain wood, convey the familiar, high Mercedes-Benz quality.

A new, ultra-fine surface structure of the standard MB-Tex dashboard is pleasant to the touch and extends across the dashboard and upper doors. Also new is a futuristic, textile-like structure in metallic silver-grey. This new Progressive Luxury is further enhanced by elegant highlights in rose-gold.

The design and interior lines: Electric Art and AMG Line

The interior line Electric Art has the design features described above with rose- gold highlights. The Mercedes-Benz EQC is also available with the sporty AMG Line, with the options of AMG Line Interior and AMG Line Exterior.

The EQC with AMG Line Exterior features an AMG-specific radiator grille and mirror housings in the vehicle color. It also looks considerably sportier thanks to a distinctive front bumper. A wide rear bumper in an AMG design further reinforces this impression. Several new AMG wheel designs in sizes between 19 and 21 inches are available for the EQC.

The interior also becomes sportier with the AMG Line Interior. In addition to a three-spoke AMG multifunction sport steering wheel with flattened lower section, the package includes an AMG sport pedal cluster of brushed stainless steel. The seats are in black MB Tex leather/DINAMICA microfiber, with leather seats and carbon-fiber look trim available as an option. AMG floor mats round off the AMG Line Interior.

MBUX: Intuitive control structure and different display styles

The information of the instrument cluster and media display is easily legible on the large, high-resolution screens. Showcasing elements in an emotionally appealing manner underlines the comprehensibility of the control structure and impresses with brilliant pixel-perfect graphics.

Depending on mood or to suit the chosen interior, the user has a choice of three different styles:

- Modern Classic is a further development of the classic display style in an elegant and light material mix.

- Sport has a high-tech turbine look with sporty black/yellow contrasts.

- Electric Art presents its digital look in reduced form. The visible color changes explain and thrill in equal measure. The glass dials change from rose-gold in Drive mode to white, and to "Electric Blue" during recuperation. The media display clearly presents functional aspects of the energy situation, including energy flow or the power consumption history.

Powertrain

Dynamic performance meets efficiency

The EQC, the first Mercedes-Benz representative of the new product and technology brand EQ, features an all-new drive system development. The interplay between dynamic performance and high levels of efficiency and comfort was a particular focus of the developers. The EQC has a compact electric drivetrain at each axle, providing the confident and sporty characteristics of an all-wheel drive vehicle. Over a wide operating range, the intelligent control allows dynamic torque distribution between the two driven axles, creating the conditions for high vehicle dynamics. The asynchronous motors have a combined maximum output of 402 horsepower. The centerpiece of the Mercedes-Benz EQC is the lithium-ion battery from in-house production housed in the vehicle floor. With a total capacity of 80 kWh, it employs a sophisticated operating strategy to supply the vehicle with power, enabling an estimated electric range of around 200 miles.

The vehicle concept of the EQC is designed for all the requirements of a battery-electric drive system. Both the electric powertrains and the battery are tailor-made for the EQC. Tractive power is provided by an asynchronous motor at each axle. The electric motor, a fixed-ratio transmission with a differential, the cooling system and the power electronics form a highly integrated, very compact unit. To reduce power consumption, the electric drivetrains are configured differently: the front electric motor is configured for best possible efficiency in the low to medium load range, while the rear one determines sportiness. Together, they generate an output of 402 hp and 564 lb-ft of torque.

Maximum variability for more efficiency and stability

In both their drive and recuperation functions, the electric motors operate and function irrespective of the direction of rotation. On the overrun or when braking, the mechanical rotation is converted into electrical energy and used to charge the high-voltage battery (recuperation). In the interests of maximum driving stability and efficiency, the power requirement between the front and rear axle is regulated according to the driving situation. Torque shifting allows the torque to be distributed between the front and rear axles, ensuring that there is always a satisfying balance between power and efficiency. This gives the EQC superior all-wheel drive driving characteristics. . Under low to medium load conditions, only the front electric motor is operated for efficiency reasons. Maximum recuperative deceleration is achieved by using both electric motors as alternators.

Extremely quiet thanks to sophisticated decoupling

Electric vehicles are commonly known to be almost silent – above all because they have no noisy internal combustion engine. However, maximum rotational speeds of around 13,000 rpm in the electric motors pose special challenges with respect to noise insulation. Mercedes-Benz engineers have achieved an impressive level of noise comfort. In the EQC the powerpacks are isolated by rubber mounts at two points: where the powerpack connects to its subframe and where the subframe connects to the body. This effective isolation is supplemented with insulation measures. As a result, the interior of the EQC is extremely quiet.

The battery: a "heart" from Saxony/Germany

The EQC is equipped with the latest generation of a lithium-ion (Li-Ion) battery serving as the energy source for both electric motors. The battery consists of 384 cells and is located in the vehicle floor, between the two axles. The battery system is modular in design, consisting of two modules with 48 cells each and four with 72 cells each. The powerful high-voltage battery has a nominal voltage of approx. 350 V and a nominal capacity of approx. 218 Ah, for an energy content of 80 kWh (according to NEDC/WLTP).

The integral overall cooling concept of the EQC, consisting of a heat pump function and two electric PTC heater boosters, not only includes the power electronics, the electric motor and the rotor, but also the battery. The entire battery system is liquid-cooled. At low temperatures a battery heater ensures outstanding performance and efficiency (see Climate control section).

The battery is an integral part of the crash concept for the vehicle as a whole. Its low, central location also has a positive effect on the handling characteristics of the EQC (see Safety section).

The battery is produced in Germany, by the wholly-owned Daimler subsidiary Deutsche ACCUMOTIVE in Kamenz/Saxony (see Production section).

As with all other high-voltage batteries, Mercedes-Benz issues a battery warranty.

Charging options: Flexible and fast charging

Whether at home via a wallbox, while shopping, at work or on the highway: there are various ways to supply electric vehicles with power. Intelligently networked charging solutions focused on the mobility needs and convenience of customers are an integral part of the new product and technology brand EQ.

Standard equipment for the EQC includes a water-cooled onboard charger (OBC) with a capacity of 7.4 kW, making it suitable for AC charging at home or at public charging stations. The charging time required for a full charge depends on the available infrastructure and the country-specific vehicle equipment. Charging at a home wallbox is much faster than at a domestic power socket (see section "The intelligent services for the EQC).

It is faster still with DC charging – which is standard for the EQC – for example via CCS (Combined Charging Systems) in Europe and the USA. This quick- charging system expands the existing technical standard for AC charging of electric vehicles with the capacity for DC fast charging. Depending on the SoC (status of charge), the EQC can be charged with a maximum output of up to 110 kW at an appropriate charging station. In around 40 minutes, the battery can be charged from 10 - 80 percent SoC (provisional data).

Energy management: The link between the battery and the power consumers

High-voltage energy management (HV-EMM) provides the link between the battery and the HV components (electric motors, air conditioner compressor, heating elements, DC/DC converter to power the 12 V components).

The functions of HV-EMM include:

- Determining the usable energy remaining in the battery

- Activation and deactivation of the high-voltage components on the basis of the available energy, and with due regard for safety requirements

- Prediction of the currently available electrical output of the powertrain

- Coordination of the charging process between the battery and charging components

- Calculation of the electric operating range and consumption for EQ- optimized navigation

Driving modes: The driver has a choice of drive strategies

The power consumption and range of electric vehicles greatly depend on driving style. The EQC supports its driver with driving modes that have different characteristics. In the more economical driving modes, the haptic accelerator pedal that prompts the driver to conserve power plays an important role.

The following programs are available:

- COMFORT: Default setting; accelerator pedal characteristic supports a comfortable driving style, but also automatically becomes more dynamic depending on the driving style.

- ECO: Driving program focused on high efficiency and low consumption.

- MAX RANGE: Intelligent driving program that can help the driver achieve the maximum possible range.

- SPORT: Driving program focused on the best response for the highest driving performance.

- INDIVIDUAL: Allows the driver to customize each individual parameter separately.

One-pedal driving: manual selection of braking recuperation

The driver is also able to influence the recuperation level using paddles behind the steering wheel. The paddle on the left increases the level of recuperation, the paddle on the right reduces it. The following stages are available:

- D Auto (recuperation via ECO Assist to suit the situation)

- D + (coasting)

- D (low recuperation)

- D - (medium recuperation)

- D - - (high recuperation). This makes one-pedal driving possible, because in most situations the recuperative deceleration is enough to not require use of the brake pedal.

ECO Assist: Intelligent efficiency through the use of sensor fusion

Predictive driving for economy - the ECO Assist assistance system comprehensively supports drivers in implementing this effective efficiency strategy: by prompting the driver when it is appropriate to come off the accelerator. For this purpose, navigation data, traffic sign recognition and information from the intelligent safety assistants (radar and stereo camera) are linked and processed.

ECO Assist takes the following traffic situations and information into account in its driving recommendations and efficiency strategy:

- Route profile (curves, intersections, traffic circles, gradients)

- Speed limits

- Distance from vehicles ahead

ECO Assist continuously generates coasting simulations in the background. Depending on the traffic situation, it computes whether the vehicle should ideally be allowed to coast with the lowest possible driving resistance with the driver's foot off the accelerator, or whether it should be decelerated so that the battery can be efficiently charged (recuperation).

Within the limits of the system, ECO Assist controls the coasting according to the situation as soon as the driver's foot leaves the accelerator. The driver is given a discreet prompt to do this by a "foot off accelerator" symbol in the media display (or in the optional head-up display). At the same time, a diagram gives the driver the reason for the recommendation ("Intersection ahead" or "Gradient ahead").

ECO Assist predictively computes the driving situation when deciding whether to drive with the lowest resistance (coasting) or whether to recuperate. Examples include downhill gradients, uphill gradients or speed limits ahead, which the system recognizes from the map data.

- Downhill Gradients: the vehicle recognizes that an upcoming downhill gradient is followed by an uphill gradient, and also recognizes the speed limit of the road. The driver receives the prompt "Foot off accelerator." As soon as the driver acts on this, the vehicle coasts with the electric motors switched off. Recuperation begins on the downhill stretch, and appropriately adjusted so that the speed limit is maintained. Recuperation ends just before the lowest point in the downhill stretch, and coasting begins to maintain as much momentum as possible for the uphill stretch in the interests of energy efficiency.

- Uphill Gradients: the vehicle recognizes that there is a speed limit of 55 mph before the top of a hill, and afterwards it increases to 60 mph at the bottom of the hill further down the road. Once again the driver is prompted with "Foot off accelerator" before the top of the hill is reached, and the vehicle begins coasting when the driver complies. On the following downhill stretch, the new target speed of 60 mph is set and maintained by the vehicle by intelligently adjusting recuperation levels.

- Speed limit: When the system recognizes a new speed limit from the navigation data or via Traffic Sign Assist, the driver is once again prompted with "Foot off accelerator pedal". The vehicle is then gently decelerated (with recuperating) to the new speed, followed by coasting. In this way, safe speeds for intersections, traffic circles and curves are also supported.

- Slow-moving traffic: when the radar sensors of the system recognize slow-moving vehicles ahead while coasting, coasting is automatically interrupted if necessary. Deceleration with recuperation takes place to the extent that braking action by the driver is often unnecessary. If the vehicle ahead accelerates, coasting is reactivated automatically so as to cease deceleration and maintain the current speed as much as possible. The driver operates the accelerator if needed.

Climate control

Pleasantly climatized interior from the start

Cars with combustion engines use their waste heat to warm the interior. Electric vehicles are more efficient – which means lower energy losses but also less waste heat to warm the interior. In other words, the engineers needed new, intelligent concepts.

A sophisticated system with a heat pump and electric heater boosters pre- climatizes the interior, ideally when charging. This increases range, as the energy requirement from the high-voltage battery can be greatly reduced. The EQC also uses the waste heat from the battery as an energy source. The integrated overall cooling concept, which cools both the power electronics and the rotors of the electric motors, is also designed for efficiency.

Thanks to pre-entry climate control, EQC drivers neither need to scrape windows nor get into ice-cold cars. And even in hot summer temperatures, the interior is cooled to a pleasant level before starting a journey. Pre-entry climate control can be controlled via the multimedia system MBUX – Mercedes-Benz User Experience – or conveniently from the home or office using the Mercedes me connect App.

Pre-entry climate control uses target values as a basis. In other words, when the driver inputs a departure time, the EQC is climatized to the set temperature by that time. The driver can do this either individually for each journey and every stretch of the journey, or with the help of a weekly schedule.

In addition to automatic air conditioning, pre-entry climate control includes heating of the exterior mirrors and rear window, as well as the seat heating for the driver and front passenger.

Sophisticated control technology: how climate comfort comes about

In the winter, many electric vehicles either fail to achieve the climate comfort of conventional cars or their range is significantly reduced because the battery power is also used to heat the interior. Furthermore, the operating temperature of the high-battery should be kept within a certain range in the interests of battery operating life, which means that it must be cooled or heated as necessary.

In the EQC Mercedes-Benz uses a sophisticated system with a heat pump function and two electric PTC (Positive Temperature Coefficient Thermistor) heater boosters. A heat pump – also familiar from domestic appliances – operates on the same principle as a refrigerator, transporting heat from a lower to a higher temperature level. This means that "cold thermal energy," which occurs particularly frequently in electric vehicles, can be used to heat the interior.

The PTC heater boosters are in principle immersion heaters whose performance is however dependent on the inflow temperature of the coolant. The advantage is that the component itself prevents overheating, making additional protection unnecessary. This is because at low temperatures, the ceramic PTC components have a very low electrical resistance and allow a high flow of current for a good heating output. The effect is reversed if the temperature rises, however: The electric current is reduced by the increasing resistance of the ceramic blocks, therefore the system releases less heat. The two PTC heater boosters in the EQC are located in the right and left wheel arches.

For the best possible climate control compromise between efficiency and comfort, the influencing factors of battery temperature, outside temperature, humidity and dewpoint are registered and evaluated. Operation of the heat pump improves efficiency over a wide outside temperature range.

Other new features in the EQC are the water-cooled condenser and regulation of the chiller (evaporator) by an electric expansion valve. This allows more usable performance, and this can be better managed. As a result the temperature at the evaporator does not suddenly change when the chiller is required to increase its performance.

The water-cooled condenser feeds the heat from the refrigeration circuit into the heating circuit. It also ensures that the heat from the supply air and recirculated air, the waste heat of the compressor and the waste heat of the battery are available to heat the interior. In the ideal case these heat sources are sufficient to heat the interior energy-efficiently with the heat pump down to outside temperatures below 0°C without having to activate the PTC heater booster.

MBUX Mercedes-Benz User Experience

Unique user experience with EQ-specific functions

The EQC features the innovative multimedia system MBUX – Mercedes- Benz User Experience – which has numerous EQ-specific functions such as displaying the range, state of charge and energy flow. EQ-optimized navigation, driving modes, charging capacity and departure time can also be controlled and set via MBUX. The MBUX display has a special EQ menu where numerous EQ features are grouped. Alternatively the user can access the EQ menu of the MBUX system directly using a key in the lower left control panel.

In the digital instrument cluster on the left side of the standard widescreen cockpit, the EQC greets its driver with an EQ welcome animation. The dial on the left shows the speed and, in the lower area, the charge status and range. The dial on the right displays the output and recuperation levels.

Under acceleration the displays behave as dynamically as the vehicle: in both dial instruments, a white band also gives a visual impression of the EQC's speed and power. A display of charging information is also part of the instrument cluster.

The media display on the right side of the widescreen cockpit has an EQ tile in its main menu as the central access point for specific displays and settings.

These include the charging current, departure time, energy flow and consumption chart. Alternatively the EQC's driver can also access this menu using a direct selection key in the lower control panel. Moreover, the EQ- optimized navigation and Mercedes me Charge functions (see Services section for details) plus the driving programs (see Drive system section) can be controlled via the media display.

The navigation screen displays charging stations and, if there is an internet connection, additional information such as availability and opening times.

MBUX - Mercedes-Benz User Experience: Intuitive to use and learn- capable

The name MBUX – Mercedes-Benz User Experience – for the new multimedia system signifies that the user experience has first priority. A unique feature of this system is its ability to learn thanks to artificial intelligence. With its predictive functions, MBUX anticipates what the user would like next. For instance, anyone who often telephones their mother on Tuesdays during the drive home will receive her telephone number as a suggestion on the display on this day of the week. Anyone who regularly switches over to a radio station with news at a certain time also receives this as a suggestion.

If the navigation system detects a route frequently driven, navigation to this destination is already started in the background. For example, MBUX suggests the gym in the navigation destination search screen. The driver then only needs to confirm they would like to proceed to the destination, and all the information on the route, such as traffic warnings, is already available.

Further strengths include the high-resolution widescreen cockpit with touchscreen operation of the media display, the navigation display with augmented reality technology (optional) plus intelligent voice control with natural speech recognition, which is activated with the keyword "Hey Mercedes."

The new Mercedes-Benz EQC under the microscope:

Voice Control

"Hey Mercedes"

One of the strengths of MBUX is its intelligent voice control with natural language comprehension, which is activated by the keyword "Hey Mercedes." The new Voice Control supports many multimedia functions (destination input, phone calls, music selection, writing and hearing messages, weather forecast), as well as numerous convenience functions such as climate control or lighting.

Conventional voice control systems in cars call for certain fixed commands from their users. However thanks to natural speech recognition, MBUX's Voice Control obeys virtually any command and recognizes and understands nearly all sentences in the areas of multimedia and vehicle operation, of course also including EQ-specific ones. For example "Where is the next charging station?" is understood, as is "Where can I charge the battery?"

The intelligent language assistance is activated either via a button on the steering wheel or with the command "Hey Mercedes." It's not the human who has to adapt to the machine, but the other way around. Indirect speech is also recognized, for instance if the user says "I feel cold" instead of giving the clear command "Temperature to 72 degrees" in order to operate the climate control. The temperature is then increased by one degree, or lowered by one degree on hearing "I am hot."

The Voice Control is also capable of learning. It tunes into the user and their voice and also understands non-native speakers better. Also, the software models on the server learn new buzzwords or changing use of language with time. The system also no longer answers stereotypically, but varies in the dialogue output too. In short: It is not the driver who must learn the voice commands stored in the vehicle, but rather the vehicle that learns the voice commands of the driver.

The fundamental way the language assistant operates: the voice input is freed from background noises, compressed and transmitted. The voice control is a hybrid system. In other words, it uses both onboard software and the cloud to understand speech as well as possible and respond to the user's requests.

Both the computer in the vehicle and the server evaluate the data and send a reply. The system decides which reply is the most likely, then within a few seconds the reply/reaction follows. This means that in contrast to many other assistants, the language assistant can also answer certain requests even when there is no internet connection.

The intelligent services relating to the EQC

Relaxed travel from start to finish

Mercedes-Benz is transforming itself from a pure vehicle manufacturer to a provider of mobility services. EQ with Mercedes me provides comprehensive services for the electric mobility of today and tomorrow. The intelligent services and functions available for the EQC extend from Route Planning and auxiliary climate control to new assistance functions and convenient charge handling. Via the EQ-optimized navigation, Mercedes- Benz customers can quickly find public charging stations, have convenient access to the charging stations of different providers via Mercedes me Charge and benefit from an integrated payment function. The objective is relaxed, uncomplicated travel with transparency and planning certainty.

Individual, specific services relating to electric mobility have been around for a while. The EQC takes a new, comprehensive approach: intelligent networking of individual services and functions make it easier for EQC drivers to use their vehicle in every phase. This already begins before the journey. Drivers are able to plan their destination and input a departure time for pre-entry climate control from their home or office desk. They not only receive an intelligently planned route including necessary charging stops and an arrival time, but also an estimate of the charge status when starting off. On request they can receive a push notification when the charging process starts and ends. This creates transparency and helps drivers to plan upcoming journeys to best effect.

The new services and functions of the EQC planned for market launch include:

Pre-entry climate control, which ensures that the vehicle interior is already at the desired temperature on departure. The EQC is correspondingly cooled down or heated. Programming is possible in several ways: directly via MBUX or via the Mercedes me App, where either an individual departure time or a weekly schedule can be entered. On request, drivers receive push notifications on their mobile phone when the process starts and ends, and are always up-to- date. Pre-entry climate control during a charging process extends vehicle range, as the energy requirement is covered by the charging current from the wallbox or public charging station.

EQ-optimized navigation operates intelligently. It uses numerous factors to plan a route automatically, including any necessary charging stops. It takes into account the current electric range, the current power consumption, which is individually determined by the driving style, the topography and the traffic flow, and available charging stations. The route calculation is always based on the fastest route taking the shortest charging time into account – with quick- charging stations as the preference. Customers do not necessarily have to charge the vehicle fully, so customers can quickly stop for a few minutes to charge and ensure it can reach the entire journey. The route planning also responds dynamically to changes. It can take place both offboard and onboard, externally (via the Mercedes me App) and within the vehicle. The journey can therefore be conveniently planned at home before departure, or while already en route if required.

EQ-specific voice control is activated with "Hey Mercedes" and its natural language recognition makes operating the EQC easier. This is because the Voice Control of MBUX recognizes and understands many questions and commands relating to electric car specific control aspects. A few examples: "Show me the energy flow," "What charging settings have been made?" "Charge the vehicle to 85 percent," "I want to leave at 8 a.m. tomorrow," or "Where is the nearest charging station?"

Convenient charging and payment

Thanks to EQ-optimized navigation, Mercedes-Benz customers can easily find charging stations either via the Mercedes me App or directly from the car, and Mercedes me Charge gives them convenient access to the charging stations of numerous providers. In this way customers benefit from authentication plus an integrated payment function with simple accounting. The customer chooses the preferred payment method only once. The individual charging processes are clearly listed in a monthly invoice.

Active safety

High stress-relieving comfort and better support in hazardous situations

The EQC is equipped with the latest-generation Mercedes-Benz driver assistance systems, which provide cooperative support for drivers. In the Driving Assistance Package, these include new functions such as predictive speed adjustment when approaching the end of a traffic jam: when traffic is detected, Active Distance Assist DISTRONIC reduces the speed as a precaution.

Drivers are familiar with this potentially dangerous situation on highways: after a curve in the road, a traffic jam suddenly appears. This is where the EQC assists its driver – by recognizing a traffic jam beforehand and responding to it.

If Active Distance Assist DISTRONIC with Route-Based Speed Adaptation is activated, the EQC is able to recognize and respond to traffic jams or slow- moving traffic before the driver becomes aware of the hazard. When a traffic jam is recognized (and if the driver does not choose a different response), DISTRONIC reduces the speed as a precaution. This can significantly reduce the risk of approaching the end of an unexpected traffic jam at high speed.

Following vehicles in a traffic jam: in stop-and-go traffic on motorways and similar roads, stops of up to 30 seconds are possible within which the EQC can automatically start up and follow the traffic ahead.

Once the traffic jam dissolves, the EQC accelerates back up to the speed preset for Active Distance Assist DISTRONIC with Route-Based Speed Adaptation.

Within the entire speed range of the EQC and on all types of roads – freeways, country roads or in urban areas – the system is not only able to automatically maintain the correct distance from the vehicle ahead, but also to give the driver noticeable steering assistance, even on bends. At speeds up to 80 mph the system can use several different methods to provide active steering assistance. If lines in the road are unclear, often in construction areas, or if there are no road markings at all, it can steer actively as if in a swarm by monitoring the vehicles around it. The system therefore makes driving much easier, especially in traffic jams.

Even in the base model, Active Brake Assist has extensive safety functions:

- an acoustic and visual warning if the danger of collision is identified

- braking assistance appropriate to the given situation as soon as the driver applies the brakes

- automatic emergency braking for moving, stationary or crossing vehicles ahead if the driver fails to respond

- automatic emergency braking also or crossing pedestrians/cyclists.

With the Driver Assistance Package, the EQC has further driving assistance systems with functions familiar from the S-Class for route-based driver support. These include further functions of Active Brake Assist, as well as Evasive Steering Assist and PRE-SAFE® PLUS if a collision threatens from the rear. The EQC also offers the Exit Warning Assist of Blind Spot Assist if a car or bicycle is detected approaching from the rear after the EQC has stopped.

PRE-SAFE®: preventive occupant protection

Mercedes-Benz is the pioneer in reversible, preventive occupant protection. These are measures that can help mitigate the consequences of accidents. With the help of various sensors and information from ESP® or the assistance systems, the PRE-SAFE® System is able to recognize critical driving situations in advance and initiate preventive occupant protection measures if an accident threatens. These include reversible belt tensioning, automatic closing of open side windows and the sliding sunroof, and movement of the front passenger seat backrest to a more favorable position in case of a collision.

PRE-SAFE® PLUS can recognize an imminent rear-end collision and the system firmly applies the brakes of the stationary vehicle, reducing the risk of whiplash injuries by reducing the forward jolt caused by an impact from the rear. This can also reduce the danger of secondary collisions, for example with pedestrians or vehicles ahead at road intersections. Immediately before impact, the PRE-SAFE® anticipatory occupant protection measures are deployed.

Passive safety

Mitigating the consequences of accidents with modern technology and the EQC-specific safety concept

When it comes to passive safety, the EQC meets the highest demands: in addition to the extensive program of crash tests, Mercedes-Benz applies further, particularly stringent safety standards to the battery and all component parts carrying electrical current.

Daimler applies extremely high safety standards to all its models. This is true for both vehicles with a conventional internal combustion engine and those with an alternative drive. This means that, in many cases, internal Mercedes-Benz safety standards exceed legal requirements. Especially the crash-related requirements are aligned to the so-called Real Life Safety philosophy. These take findings from in-house accident research into account in the development specifications. Alongside verification of crash behavior, all Mercedes-Benz vehicles undergo additional component tests at system level.

The vehicle structure of the EQC allows for the special requirements of the electrical components and battery and is configured to achieve the hallmark high safety level. For example, a new subframe surrounds the drive components located in the front section, and this unit is supported by the usual mounting points. As the battery is housed in the vehicle floor, the EQC also has a low center of gravity. This reduces the risk of a rollover.

Crash gaps are integrated between the fenders and the doors, and like the robust door handles they make it easier to open the doors after a frontal collision.

The high-voltage system: disconnecting in the event of a crash

The extensive experience of Mercedes-Benz with high-voltage drive systems has led to a multi-stage safety concept that deploys in the event of an accident.

Thanks to the specific design features of the EQC, the likelihood of an external short circuit caused by an accident is considerably reduced. The battery is surrounded by a robust frame with an integral crash structure. Deformation elements are installed between the frame and the battery, and these are able to absorb additional forces in the event of a severe side impact.

A battery guard in the front area of the battery is able to prevent the energy storage unit from being pierced by road debris.

The high-voltage system can also be shut down automatically in a crash, depending on its severity. A distinction is made between a reversible and an irreversible disconnect. In the case of a reversible disconnect, which occurs in less severe accidents, it is possible to switch the high-voltage system back on if it detects no faults. This means that vehicles would still capable of being driven, and the driver can then continue their journey. Only in the case of very severe accidents, where the vehicle is heavily damaged, is the high-voltage system shut down irreversibly and unable to be activated without a repair. When shutting down, there is a provision to ensure that within a few seconds there is no residual voltage in the high-voltage system outside the battery that could cause injury.

There are also shutdown points where emergency teams can deactivate the high-voltage system manually. The cut-off switch is located in the engine compartment. In addition, there is a marked cable loop that can be cut in the fuse box on the driver's side as an alternative shutdown point. This is intended for use by the emergency services if they are unable to reach the shutdown switch in the engine compartment.

Another feature of the comprehensive high-voltage safety concept is that the charging process is automatically stopped if an impact is detected while the vehicle is parked at a quick-charging station (DC charging).

The battery: multi-stage protection concept for normal operation

The battery itself also features its own multi-stage safety system for day-to-day operation. This includes monitoring the temperature, voltage and insulation. In normal operation, if a fault is detected, it can lead to the battery being shut down. A continuously self-monitoring safety system prevents overheating and overloading in different operating states.

Restraint systems: Belts and airbags

In addition to the structural safety and the battery protection concept, the model's specially adapted restraint systems are particularly important for the occupants in the event of an accident. Three-point seat belts with pyrotechnical belt tensioners and belt force limiters are installed for the driver, front passenger and passengers on the outer rear seats. The center seat of the second row is equipped with a standard three-point belt system.

ISOFIX child seat anchorage points on the outer rear seats ensure safe attachment of appropriate child seats with additional anchorage points at the top of the rear seat backrest (top-tether anchoring). If the front passenger seat is unoccupied or a rear-facing child seat is detected, the "automatic front passenger airbag deactivation" automatically disables the front passenger airbag. This prevents infants from being injured by the deploying front passenger airbag. The reliable recognition function uses a pressure sensor.

In addition, a host of airbags provides occupant protection in an accident. These include:

- A curtain airbag in the roof area between the A, B and C-pillars for the head area of the driver, front passenger and passengers on the outer rear seats. These airbags can be deployed on a situational basis, for example during a severe lateral impact, when a rollover is detected or in various frontal collisions with strong lateral acceleration components.

- Combined thorax/pelvis side impact airbags for the driver and front passenger, which are able to provide additional protection in the event of a side impact. Side impact airbags for the outer rear seats are available as an option.

- Airbags for the driver and front passenger for a frontal collision, with two-stage staggered deployment on the front passenger side, depending on the detected severity of the frontal collision.

- Knee airbag for the driver to protect the knees in a severe frontal collision and stabilize the upper body, which positively influences occupant movement.

Numerous measures help to ensure that when Mercedes-Benz vehicles are involved an accident, consequential damage is reduced and rescue of the occupants is assisted. As soon as a protective system is triggered, an emergency call or a service call is made. The following measures can be initiated depending on the accident type and severity:

- Automatic activation of Mercedes-Benz emergency call to notify emergency services of the location and emergency situation and initiate rescue. Data transfer is via a communication module with its own SIM card.

- Shutdown of the high-voltage system

- Activation of the hazard warning system to alert other drivers of an accident and protect occupants from additional accidents.

- Activation of the interior lighting to help occupants and rescue services.

- Lowering of the front side windows in the event of airbag deployment – serves to ventilate the interior and help occupants.

- Unlocking the doors to facilitate access to the interior for emergency services.

- Raising of the electrically adjustable steering column; facilitates exiting and access to the driver.

- Sending a recognized breakdown or accident situation to the Car-to-X Communication and to the Mercedes-Benz Service Center (Mercedes me or Service Call) to give a warning of an accident or broken-down vehicle, and to offer the driver automatic contact with the Mercedes- Benz Service Center.

Digital support for emergency services: QR code and Rescue Assist App

With a small but effective innovation, Mercedes-Benz has also found a way to give rescue services the best possible support and a clear overview of the vehicle's safety-related features.

The digital Mercedes-Benz rescue helpers interact perfectly: The Rescue Sticker provides a direct link to the vehicle's rescue data sheet. Corresponding stickers are affixed to the charging flap and to the opposite B-pillar of the vehicle for this purpose. In the aftermath of an accident, rescue services can scan the QR code with a smartphone or tablet PC for fast and reliable access to the rescue data sheet for the specific vehicle involved, thus facilitating rescue operations.

Alongside the rescue data sheets, the Rescue Assist App for smartphones and tablets also has three-dimensional views of the vehicle – now also available offline in case there is no mobile network available at the accident scene.

To ensure practicality, the Mercedes-Benz safety team develops its rescue information and processes together with the fire and rescue services.

Testing

Endurance tests around the globe: on the road to series production

By the time of the global market launch, prototypes and pre-series versions of the EQC will have covered several million miles throughout testing on four continents (Europe, North America, Asia and Africa). The test program comprises more than 500 individual tests. Like all Mercedes-Benz vehicles, the EQC must pass the demanding standard test programs. There are also special tests for the electric powertrain, the battery, and the interplay of all powertrain components. In the process the test experts are able to build upon the extensive findings from their digital testing work, used to ensure both the buildability of the vehicle and for the simulation of e.g. crash behavior, aerodynamics and NVH (noise, vibration, harshness). In addition, there are intensive tests on numerous test rigs at the Mercedes-Benz Technology Center in Sindelfingen, Germany. The ratio between digital and real testing is roughly 35 to 65 percent.

Testing of the EQC began on a computer long before the first prototypes were ready to drive. One special feature affecting the handling characteristics is the low center of gravity thanks to the location of the battery in the underfloor area. As early as the planning phase, and on the basis of available design and functional data, simulations were carried out to determine the vehicle dynamics and handling safety.

Stability at high speed, ride comfort, yaw and steering behavior when cornering (understeer or oversteer) as well as braking stability were already predicted very precisely in this early development phase. In addition a real ESP® (Electronic Stability Program) system was connected to a simulation model. This allowed very precise predictions of behavior with respect to vehicle dynamics and handling safety.

Digital testing in 3D

Assemblies from the future vehicle were three-dimensionally projected in the Virtual Reality Center (VRC) on the basis of design and surface data – even entire vehicles can be photo-realistically represented here. The projections are jointly viewed by the design and test engineers, and assessed as if in a real vehicle according to standardized test stages in what amounts to a "stationary test drive". In this way it is possible to assess around 30 percent of the over 1000 standardized test stages in the digital vehicle as if a real road test was being conducted. The assessments include the opening angle of the tailgate, the swept area of the windshield wipers or the controlled dripping of water when opening a door after a rain shower.

Many details relating to the acoustics can also be evaluated in advance. The test engineer views the dimensions, thickness, size, installation location and material of the respective insulation components, and approval is given after a positive assessment together with the design engineer. Another example is testing and assessment of potential chafing: in this case the test engineer views the routing of flexible components such as hoses and wiring harnesses at a very early stage to identify potentially critical areas. The crash behavior, aerodynamics and even the handling dynamics are also verified at an early stage by simulations: Assessments can be made on the basis of the steering, the geometrical layout of axle components and the wheel control. The basic situation is this: the more detailed the data preparation, the more aspects can be assessed more precisely.

From computer screen to dynamometer...

The next step was component testing on numerous test rigs and facilities. For example, the suspension engineers used the driving simulator at the Mercedes- Benz Technology Center (MTC) in Sindelfingen to test and verify the comfort and handling characteristics of the EQC long before drivable prototypes became available.

The simulator for ride comfort (suspension comfort) was used to subjectively experience and assess the comfort performance of the EQC at an early stage. This means that the real testing commenced from a considerably better starting level. As a result, the engineers in the later development phase had more time for fine-tuning work.

More than 70 configurations possible: Crash-testing in the TFS

The safety of the EQC was validated at the Mercedes-Benz Technology Center for Vehicle Safety (TFS), which opened in November 2016 as the world's most cutting-edge crash test center. The special features of the center include a crash facility measuring 295 x 295 feet which has no supporting pillars. This obstacle-free area makes it possible to test pre-crash systems in the pre- accident phase, and to conduct vehicle-to-vehicle crash tests. The flexible and efficient crash track concept allows complex testing in around 70 different crash test configurations.

The new crash tests now possible include the following:

- Accidents at road intersections (both vehicles are moving and collide at selectable angles and speeds, with one vehicle sustaining a side impact).

- Car2Car compatibility crash tests.

- Driving maneuvers for realistic representation of the pre-accident phase enable new assistance and PRE-SAFE® systems to be tested.

- Car2Car testing with angle of impact from 0°-180°.

In addition to the Mercedes-Benz specific roof drop test, new rollover tests are also possible in which a new inclined ramp is used. In this test the vehicle is accelerated on a 6.5-ft high sled and fed onto the inclined ramp (ramp length approx. 65 ft). The ramp angle can be adjusted from 25° to 50°. The rollover tests are used e.g. to verify the airbag deployment logic and validate the automatic emergency call systems.

The decisive factor for the EQC was that all the safety precautions were taken in the Technology Center to be able to test prototypes with large electric batteries under hard crash conditions at a very early development stage. This is because vehicle safety not only includes assessment of the effects on occupants during a crash, but also the crashworthiness of the battery. During the course of this development, a number of measures described in the section on "Passive safety" were taken.

The battery components were tested in parallel at the development center of Deutsche ACCUMOTIVE, a wholly-owned Daimler subsidiary. Test criteria included the battery's behavior under impact and when penetrated by foreign objects, with overheating and overloading also tested.

Details of the high-voltage safety concept can also be found in the section on "Passive safety."

Thunder and lightning: The storm takes place in the laboratory

In the climatic wind tunnels in the immediate vicinity of the TFS, the EQC was not only aerodynamically fine-tuned - its body, drive system and air conditioning were also tested under laboratory conditions in the most extreme weather. Temperatures ranging from minus 40 to plus 140 degrees Fahrenheit, hurricanes wind speeds of up to 165 mph, tropical downpours and heavy snowstorms are all part of the standard repertoire available to the test engineers. Is the body weatherproof? How long does it take iced-up windows to thaw? Does the air conditioning system also keep the windows clear in extreme air humidity? Can the doors also be opened in very low temperatures? These are just some of the many questions that are investigated.

… And from the dynamometer to the road

After the first prototypes were roadworthy, the summer and winter road testing of the EQC began. Test drives were carried out on numerous sites in Arjeplog (Sweden), near Barcelona (Spain), in Phoenix (USA), in Peking, Heihe and Chengdu (China) and in Boxberg and Papenburg (Germany). Even before its official opening, tests are also being carried out on the new Daimler test site in Immendingen (Germany) this year. The road tests took the test teams all over Europe, e.g. to the Sierra Nevada (Spain) and the low mountain ranges of the Swabian Alb and the Black Forest in Germany.

The test program comprised more than 500 individual tests, which in addition to the standard test regimen for all vehicles also included special tests for the electric powertrain, the battery and the interplay of all powertrain components. The special endurance tests also include a taxi-test, which represents urban driving with frequent idle times, and the high-mileage driver cycle where the focus is on high daily mileages.

Hot on ice: Winter trials

Mercedes-Benz has been testing each new model under extreme conditions near the Arctic Circle for decades – in icy temperatures down to minus 31 degrees Fahrenheit, on snow-covered roads and on sheer ice on frozen lakes. To this end, Mercedes-Benz has set up a test center in the small northern Swedish town of Arjeplog in Lapland. In addition to the road testing in the far north, tests take place on specially set-up testing tracks here. Demanding hill climbs with gradients of up to 20 percent, test tracks with varying coefficients of friction, handling courses, and skid pads on the almost sheer ice of a frozen lake pose the stiffest of challenges for the powertrain and control systems.